Description

Product Description

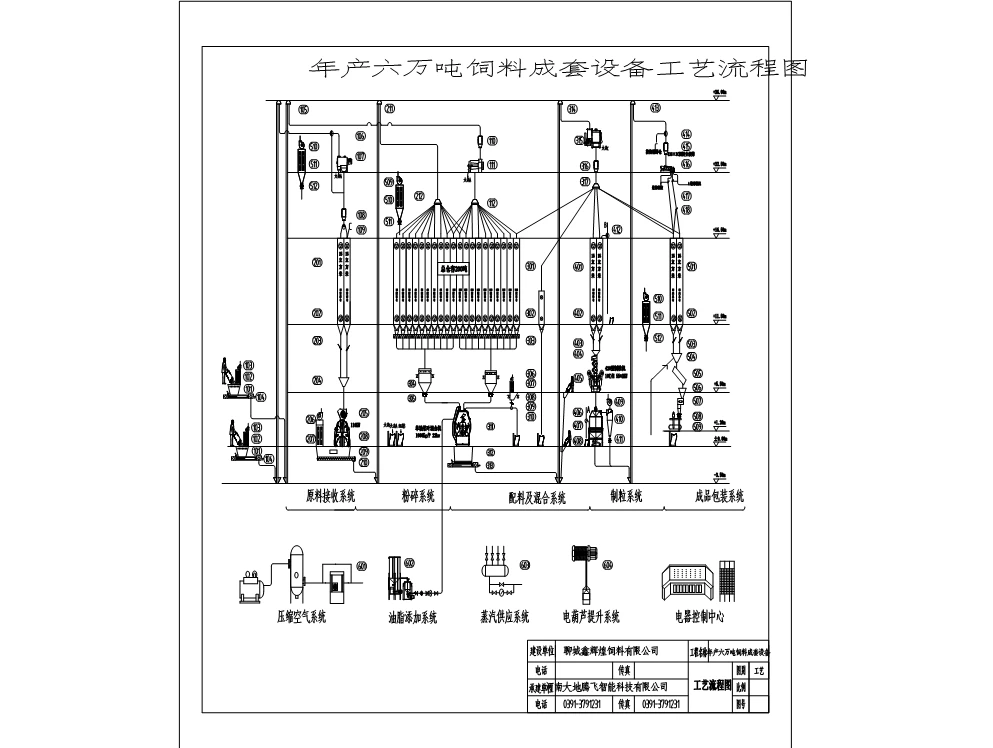

1.This Poultry Feed Making Machine can be used to make feed pellets for all ages of chicken. And it is a good choice for the farm owner and those who plan to step into the poultry feed-making industry. Reasons: 1. they don't have enough experience in making poultry feed, but they have known enough knowledge about how to raise chickens, which is more convincing when they sell the pellets. 2. The capacity is not big, which can fulfill their requirement for their own farm use, reducing the cost; and the capacity is not too small, take 10 hours working per day, the output for one day is about 10 to 40 tons, which means at least in the 10 years, the capacity of this Animal Poultry Feed Pellet Mill Equipment can meet the requirement of the market; 3. The total investment for this Animal Poultry Feed Pellet Mill Equipment is not big, which also reduces the risk.

Main Features

1.With two rollers inside, better for poultry feed making;

2.Manufacturing according to internationally advanced technology standard;

3.The quality matching with the European standard;

4.Gear driving system, with good transmission rate, stable and reliable performance and low noise;

5.The key components are imported to ensure longer service life and lower cost for maintenance;

6.Raw material contacting parts are made by stainless steel;

7.Widely used for pelleting the high-grade livestock and poultry feed.

2.Manufacturing according to internationally advanced technology standard;

3.The quality matching with the European standard;

4.Gear driving system, with good transmission rate, stable and reliable performance and low noise;

5.The key components are imported to ensure longer service life and lower cost for maintenance;

6.Raw material contacting parts are made by stainless steel;

7.Widely used for pelleting the high-grade livestock and poultry feed.

Specification

|

Model

|

Main Power

|

Feeder Power

|

Conditioner Power

|

Dia.of Ring

|

Pellet Size

|

Capacity

|

|

SZLH250

|

22KW

|

0.55KW

|

1.5KW

|

250mm

|

φ1.0-12.0mm

|

1-2T/H

|

|

SZLH320

|

37KW

|

1.5KW

|

2.2KW

|

320m

|

φ1.0-12.0mm

|

3-5T/H

|

|

SZLH350

|

55KW

|

1.5KW

|

3.0KW

|

350mm

|

φ1.0-12.0mm

|

5-8T/H

|

|

SZLH420

|

110KW

|

2.2KW

|

7.5KW

|

420mm

|

φ1.0-12.0mm

|

8-12T/H

|

|

SZLH508

|

132/160KW

|

2.2KW

|

11KW

|

520mm

|

φ1.0-12.0mm

|

12-18T/H

|

Details Images

1. Hammer Mill

Widened grinding surface, fully optimized hammer arrangement, wonderful performance for micro grinding.

Forward and reverse work of rotor, the longer service life of the hammer.

High-precision dynamic balance detecting rotor, little vibration, low noise.

2. Horizonal type mixer

Check by the State General Administration of quality supervision inspection, mixing evenness maximum 97.7%(the C.V.2.3%), normal residue ≤0.1%, tons of power consumption is only 0.3kw.h/h.

The filling coefficient variable scope is 0.4~1, widely used in many industries in the different proportions, size,s and other materials mixed.

3. Intermittent Liquid Adding System

Applied to add a variety of oils and other liquid nutrients to the mixer for each batch of 50, 100, 200 kg.

Automatic control of liquid temperature and level in the tank from the microcomputer, triple coverage, accurate.

Equipped with auxiliary booster device to eliminate oil dripping after stop, in order to avoid material agglomeration problem.

4. Pellet Machine

It can make pellet size from 1.5mm-8.0mm.

High efficiency reach 98%-99%,Long lifetime,working stable,high reliability.

5. Counterflow type cooler.

This cooling machine is used to cooled down the pellets to the room temperature, which make them easy to store.

This cooling machine is used to cooled down the pellets to the room temperature, which make them easy to store.

6. Rotary screener.

This machine is used to selected the qualified pellets. It has three outlets. The qualified pellets will flow to the packing, smaller pellets will be sent to remake pellets, bigger pellets will be sent for rebreaking.

This machine is used to selected the qualified pellets. It has three outlets. The qualified pellets will flow to the packing, smaller pellets will be sent to remake pellets, bigger pellets will be sent for rebreaking.

7. Pulse dust collector.

Used to collect the dust and the materials.

Used to collect the dust and the materials.

Bucket elevator.

This machine is used to deliver materials to the next system.

This machine is used to deliver materials to the next system.

screw conveyor.

this machine is under the hammer mill, function is to help the hammer mill to get higher capacity.

this machine is under the hammer mill, function is to help the hammer mill to get higher capacity.

Palletizing robot

Handling speed: 1200 bags/hour 24 hours continuous work Maintenance cost 160 USD/year

Handling speed: 1200 bags/hour 24 hours continuous work Maintenance cost 160 USD/year

Application