SZGH

Metal 2 axis Turning CNC Lathe Machine Slant Bed CNC Lathe

- SKU:

- 206568891011181

- Shipping:

- $929.87 (Fixed Shipping Cost)

Description

Product Overview

Factory SZGH CE Approved China High Quality Metal Processing Automatic CNC Turning Lathe CNC Machine Price

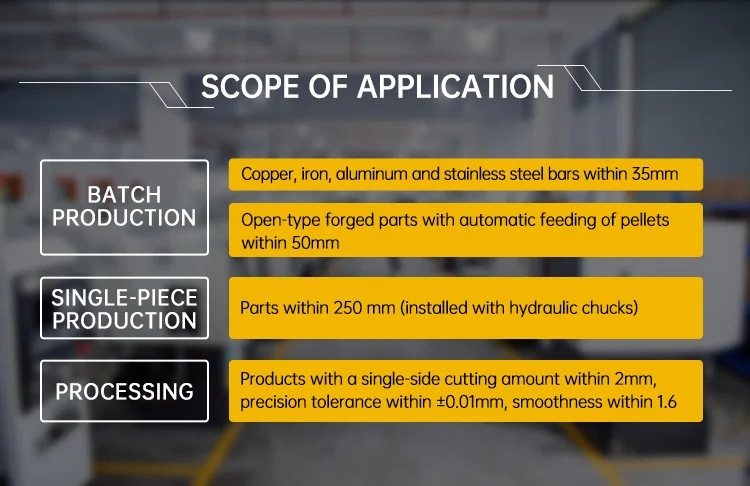

It is suitable for mass production of copper, iron, aluminum, stainless steel bars within 35mm, and automatic feeding of forgings and other pellets within 50mm. Using a number of patented technologies such as high rigidity and anti-deformation structure, it is suitable for processing products with a single-sided cutting amount within 2mm, precision tolerance within ±0.01mm, and smoothness of 1.6. It is widely used in the upgrading of hard rail CNC lathes, cam automatic lathes and hydraulic lathes, realizing automatic production to save labor costs and improve product quality.

Standard Configuration

|

Project

|

Unit

|

Standard value

|

Max value

|

||

|

Processing capacity

|

Max. diameter of bar bore/ bar capacity

|

mm

|

35

|

-

|

|

|

Max. particle diameter (disk type)

|

mm

|

250

|

300

|

||

|

Max. length of workpiece

|

mm

|

210

|

230

|

||

|

Cutting amount of stainless steel on one side

|

mm

|

2

|

3

|

||

|

Machining accuracy of the workpiece

|

mm

|

±0.01

|

-

|

||

|

Surface roughness

|

Ra

|

1.6

|

-

|

||

|

the height of center tool holder

|

mm

|

40

|

-

|

||

|

Turning Diameter

|

mm

|

350

|

-

|

||

|

Square Knife Specifications

|

mm

|

16

|

-

|

||

|

Travels

|

X-axis effective travel (diameter)

|

mm

|

600

|

-

|

|

|

Z-axis effective travel

|

mm

|

230

|

-

|

||

|

Feed |

X-axis rapid traverse

|

m/min

|

25

|

30

|

|

|

Z-axis rapid traverse

|

m/min

|

25

|

30

|

||

|

X-axis servo-motor power

|

kW

|

1.3

|

-

|

||

|

Z-axis servo-motor power

|

kW

|

1.3

|

-

|

||

|

Spindle

|

Max.Spindle Speed

|

rpm

|

3500

|

4000

|

|

|

Spindle Motor Power

|

kW

|

3

|

-

|

||

|

Spindle nose taper

|

-

|

A2-4

|

-

|

||

|

Support hydraulic chuck size

|

inch

|

6

|

8

|

||

|

Dimensions |

Dimensions

|

mm

|

1750*1400*1800

|

-

|

|

|

Total Weight

|

kg

|

1800

|

-

|

||

|

Fully enclosed splash guard with top roof

|

3KW spindle servo motor

|

Telescopic guards for X/Z axes

|

|

Spindle speed 4000 rpm, A2-4

|

Automatic lubrication system

|

Coolant system

|

|

Lubrication system

|

Hydraulic system

|

Coolant tank

|

|

Oil separator

|

LED working lamp

|

Electronic handwheel (MPG)

|

|

Coolant gun

|

Toolbox and user manuals

|

The tool holder(5 Sets)

|

|

Collet (1 Set)

|

C axis

|

CNC Simulation

|

CNC CONTROLLER SYSTEM

1) 800x600 8.4 inchs real color LCD displayer.

2) Support PLC and macro function, and automatic tool exchange function.

3) 128MB Memory , 100Mb user store room.

4) 5MHz Pulse Output Frequency, Max speed is 300m/min, feeding speed is 150m/min.

5) Adapted servo spindle can realize spindle continous position,rigid tapping,rigid screw processing.

6) High anti-jamming switch power(220VAC -> 24V&5VDC).

7) Built-in many plc programs,which can be edited freely.

8) With USB interface,it supports file operation in flash disk,system configuration and software upgrade.

9) Display in chinese or english,which can be selected by parameter.

10) Analog voltage output of 0~10V in two channels,support double spindles.

11) 32 bits high performance, low power consumption industrial grade ARM11 microprocessor.

12) I/Os : 56*32, 40*32 I/Os can be edited freely.

13) cutter offset : C.

14) English menu, program and interface, full screen edition.

2) Support PLC and macro function, and automatic tool exchange function.

3) 128MB Memory , 100Mb user store room.

4) 5MHz Pulse Output Frequency, Max speed is 300m/min, feeding speed is 150m/min.

5) Adapted servo spindle can realize spindle continous position,rigid tapping,rigid screw processing.

6) High anti-jamming switch power(220VAC -> 24V&5VDC).

7) Built-in many plc programs,which can be edited freely.

8) With USB interface,it supports file operation in flash disk,system configuration and software upgrade.

9) Display in chinese or english,which can be selected by parameter.

10) Analog voltage output of 0~10V in two channels,support double spindles.

11) 32 bits high performance, low power consumption industrial grade ARM11 microprocessor.

12) I/Os : 56*32, 40*32 I/Os can be edited freely.

13) cutter offset : C.

14) English menu, program and interface, full screen edition.

spindle

The self-made high-speed paired bearing unit spindle adopts angular contact high-speed bearings, and the normal speed is 3500/min, which is suitable for large-scale machining. The clamping method can be changed from hydraulic to pneumatic clamping according to different usage occasions of customers. If high-speed and high-gloss requirements are required, a 6000-rpm high-speed electric spindle can be selected.

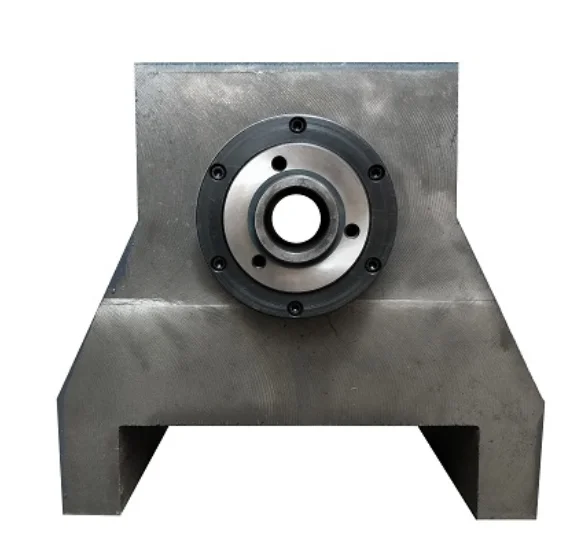

Rotary Cylinder

The standard configuration adopts a hydraulic rotary cylinder to make the clamping force stronger, more stable and have a longer service life. It can be replaced with pneumatic clamping according to the actual situation.

ball screw

Taiwan brand 25 mm ball grinding precision grade screw rod

Machining of long shaft workpieces

It can realize the processing of 120mm long workpiece with the nozzle holder.

Linear Guides

Taiwan brand 25mm Linear Guides precision grade

Optional Accessories

Application