Description

Product Description

|

Max.swing over bed

|

300mm

|

|

|

Distance between centers

|

700mm

|

|

|

Swing over cross slide

|

175mm

|

|

|

Spindle bore

|

38mm

|

|

|

Taper of spindle bore

|

MT5

|

|

|

Cross slide travel

|

140mm

|

|

|

Top Slide travel

|

80mm

|

|

|

Number of metric threads

|

18

|

|

|

Number of inch thread

|

21

|

|

|

Range of metric threads

|

0.2-3.5mm

|

|

|

Range of inch threads

|

8-56 1/n"

|

|

|

Range of longitudinal feeds

|

0.07-0.65mmr

|

|

|

Tailstock quill travel

|

94mm

|

|

|

Taper of tailstock quill

|

MT3

|

|

|

Number of spindle speeds

|

continuously variable

|

|

|

Range of spindle speeds

|

30-3000r/mim

|

|

|

Motor power

|

1500W

brushless constant torque variable frequency motor

|

|

|

Machine size

|

1250*650*870mm

|

|

|

Packing size

|

1400*750*1010mm

|

|

|

Net Weight/Rough Weight

|

300/340kg

|

|

|

Milling Head

|

||

|

Taper of spindle bore

|

MT2

|

|

|

Spindle drilling capacity

|

20mm

|

|

|

Max milling capacity

|

16mm

|

|

|

Max facing capacity

|

63mm

|

|

|

Travel of spindle

|

50mm

|

|

|

Width of T-groove

|

10mm

|

|

|

Range of spindle speeds

|

50-2250R/MIM,continuously variable

|

|

|

Motor power

|

750W

|

|

|

Output voltage

|

220V/available customized

|

|

grating scale

grating scale is available to be added.

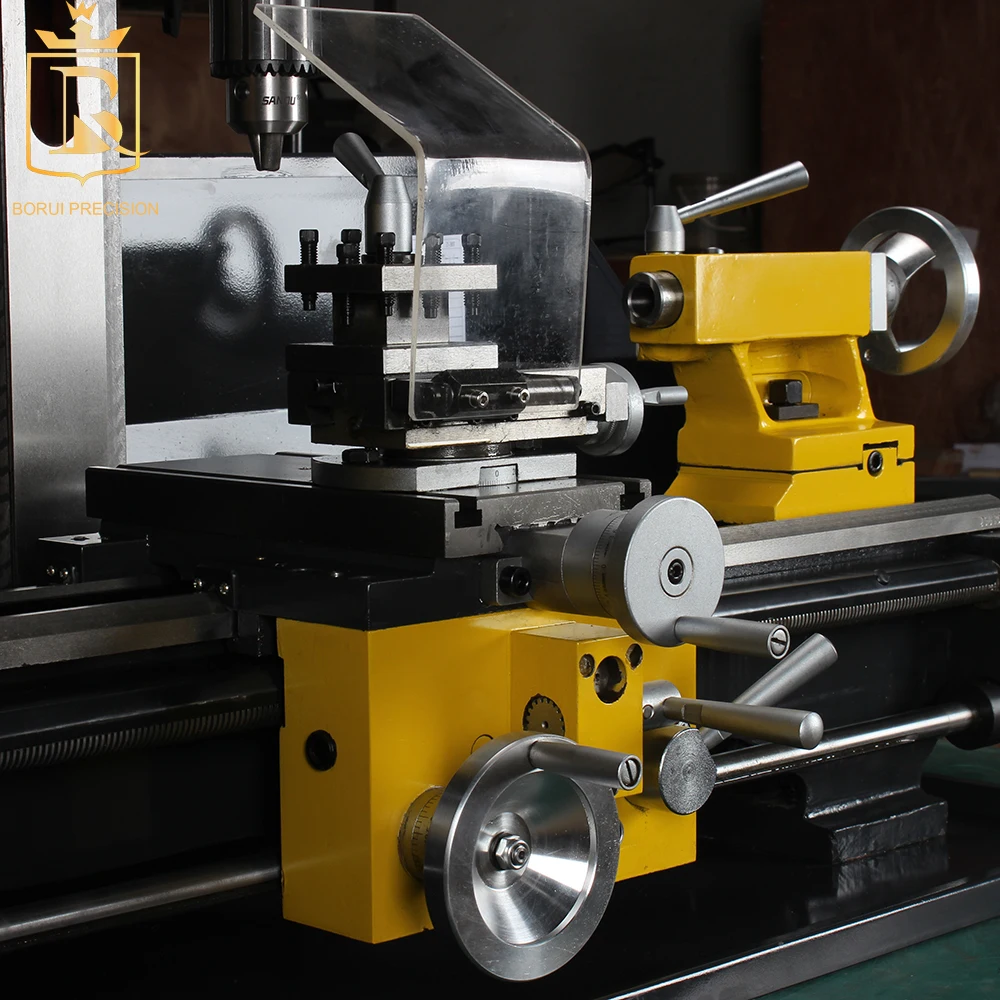

Detailed Images

Master Control Switch

*Siemens contactor

*Delta inverter

*Kedu switch

The safety of the electrical appliances is guaranteed by the European CE certification. The electromagnetic switch is equipped with switch stop and switch. The classic combination is stable and durable

The chuck can be easily replaced by rotating the locking disc after only three nuts need to be loosened

Sliding Box

Automatic knife control handle:

Open and close can be controlled easily by lifting the handle upward and downward. The nut is made of all-copper with good wear resistance and long service life

Open and close nut handle:

When the screw gear position is hung and the handle is pressed down, the set pitch can be released

Adopt 1000W brushless dc motor, unique low speed gear, can more leisurely processing of some high hardness materials.The new transmission scheme avoids the disadvantages of traditional transmission, such as loud noise, high oil leakage and seepage failure rate, and difficult maintenance.Suitable for customers with high requirements on noise and sanitation

Real double lever:

Full gear change feed box, can control the direction of the knife and knife speed and lead screw and light bar between the switch

Prevent overload:

The use of real parallel bars design above the lead screw, the following light bar.Light bar automatic knife function.Horizontal and vertical automatic knife.When machining parts, the knife is more uniform cutting force, higher efficiency.We specially designed light bar overload protector.In the case of overload, the clutch power transmission will instantly disengage, which can effectively protect the operation safety of the machine

Double lock

Unique two kinds of locking mechanism, in the case of large load using nut locking, locking force stability.General processing of the use of fast locking handle, locking speed is fast and easy to operate.

Middle wheel wrench

In the middle support plate precision thickening design good rigidity on both sides of T groove can be convenient and flexible to fix different fixtures, more convenient to use, the tool rest can be removed as a whole, only need to loosen 2 screws can be out of the full proof of the workbench, convenient drilling and milling processing

Serial number

Each machine tool has a unique number.The number can be traced back to the assembly workers, inspectors and storage time of each machine tool, so as to control the quality more strictly.

Quenching lathe bed

High grade cast iron bed, natural aging by long time.High frequency quenching has good positioning accuracy and excellent cutting performance.

Standard Fittings